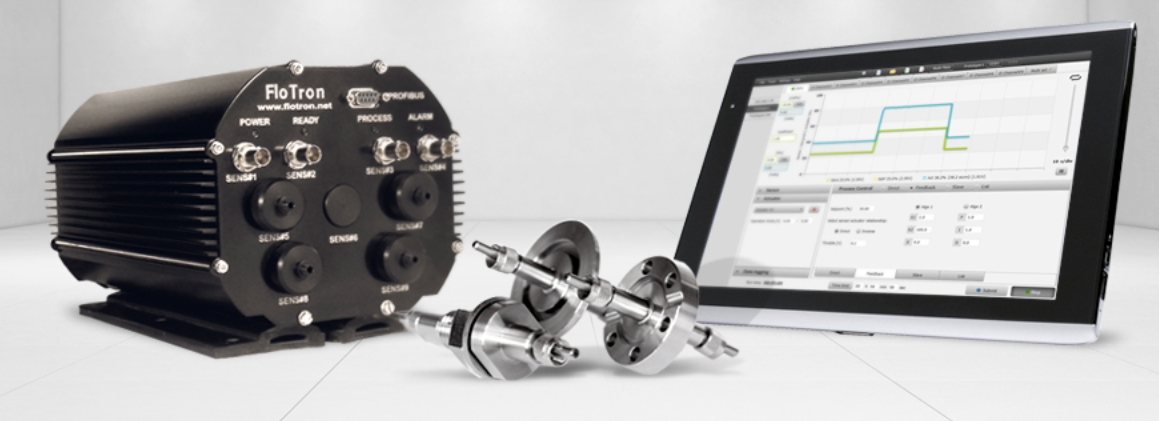

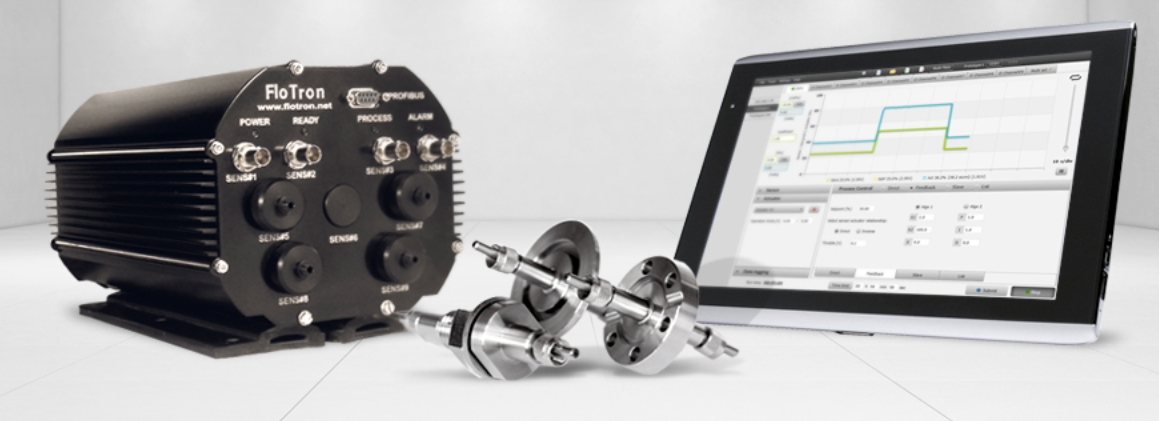

THIN FILM CONSULTING provides the novel high-speed FloTron™ plasma emission monitoring (PEM) system for process monitoring and real time in-situ control of reactive sputtering, ion- and plasma processing.

In a reactive sputtering process a metalllic target is sputtered in the presence of a reactive gas that will react with the target material to form a coating of different chemical composition. The FloTron™ system enables a stabilized working point in the potentially unstable “transition” regime between metallic and fully oxidized sputtering mode.

Working in the transitions region increases efficiency and economy of thin film production. It features:

- higher deposition rate by a factor of 2 - 4

- better process stability and repeatability

- improved film properties

- fine tuned chemical composition

- better control of uniformity

Applications: R&D processes with a high speed and high resolution spectrometer

- industrial coating deposition for Roll-to-Roll- or Inline-Coaters

- reactive magnetron sputtering

- reactive HiPIMS sputtering

- reactive arc evaporation

- reactive evaporation with electron beam guns

FloTron™: An outstanding reactive sputtering process control system:

- innovative and fast pseudo derivative feedback (PDF) control algorithm

- simple, intuitive Graphical User interface (GUI) free of charge

- fast and easy integration via PROFIBUS, PROFINET, Ethernet/IP ...

- economic single wavelength Photomultiplier (PMT) based sensor

- multi-wavelength CCD-Spectrometer based sensor

FloTron™ offers a flexible sensor concept that fits almost any need and budget:

- PEM “Single wavelength”: PMT + narrow-band-pass filter

- PEM “Broadband/multiple wavelength”: CCD/CMOS Spectrometer

- Sputtering Target Voltage (plasma discharge impedance)

- Partial pressure (p.p.) of reactive gas (e.g. O2 via Lambda-Sensor)

Benefits from FloTron™

- better run-to-run repeatability

- enhanced productivity

- improved machine economy

- process quality data logging

- maintain film properties for whole target life

- system implementation with onsite- or remote support

- customer training

The FloTron™ X HR is a high resolution plasma OES and process control system that comprises a 200-1100 nm UV-VIS-nIR CCD spectrometer detector range with better than 0.5 nm optical resolution.

This makes FloTron™ X HR a perfect and preferred plasma OES instrument, which allows accurate plasma parameter identification and reliable determination of plasma characteristics. It is therefore highly suitable for process monitoring and/or control applications, where multiple and otherwise difficult to resolve plasma emissions are important.

FloTron™ X HR is applicable to vast technical fields covering the majority of technological plasma processes (e.g. vacuum, atmospheric, water-based, etc.). It is perfect for R&D and suitable for pilot as well as (in certain cases) 24/7 mass production.

Same as every other product in the growing FloTron family, the X HR also brings state-of-the-art feedback control, high accuracy, excellent long-term stability and reproducibility as well as COST EFFECTIVENESS and easiness of integration into existing or OEM systems.

Download the document below to check important FloTron™ X HR specifications, advantages and features: FloTron X HR, High Resolution, OES, PEM, 2015