IONIX® circular HV flange mounted solutions

All IONIX® HV sputtering sources in the range of 2'' - 6'' (Ø50 - 152.4 mm) can be mounted to a wide variety of flange sizes (eg. DN100SIO - DN200ISO) and configurations incorporating shutters, chimneys, tilts, z-shifts and gas distributions. Utilizing a manual or insitu-tilt the focal point of the sputtering source can be adjusted for different target-to-substrate distances and target materials.

- for target-Ø 50 – 152.4 mm (Ø 2“- 6“)

- pneumatic shutters

- gas distribution

- z-stroke 100 mm

- +/- 45° tilt or 40° instu-tilt

- flanges DN100ISO - DN200ISO

Technical data

| IONIX® Ø2'' HV | IONIX® Ø3'' HV | IONIX® Ø4'' HV | IONIX® Ø6'' HV |

|

|

|

|

| Read more-> | Read more-> | Read more-> | Read more-> |

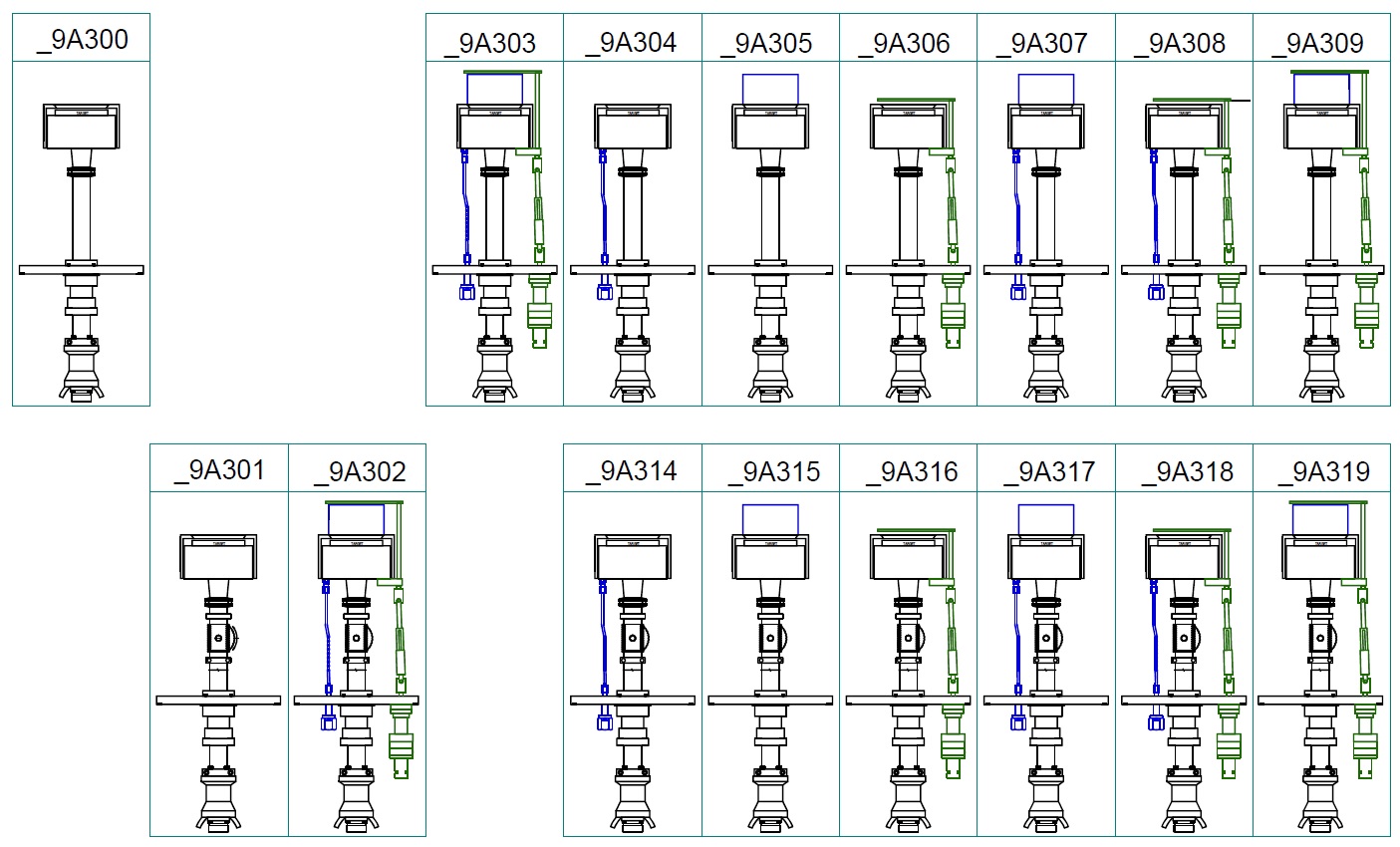

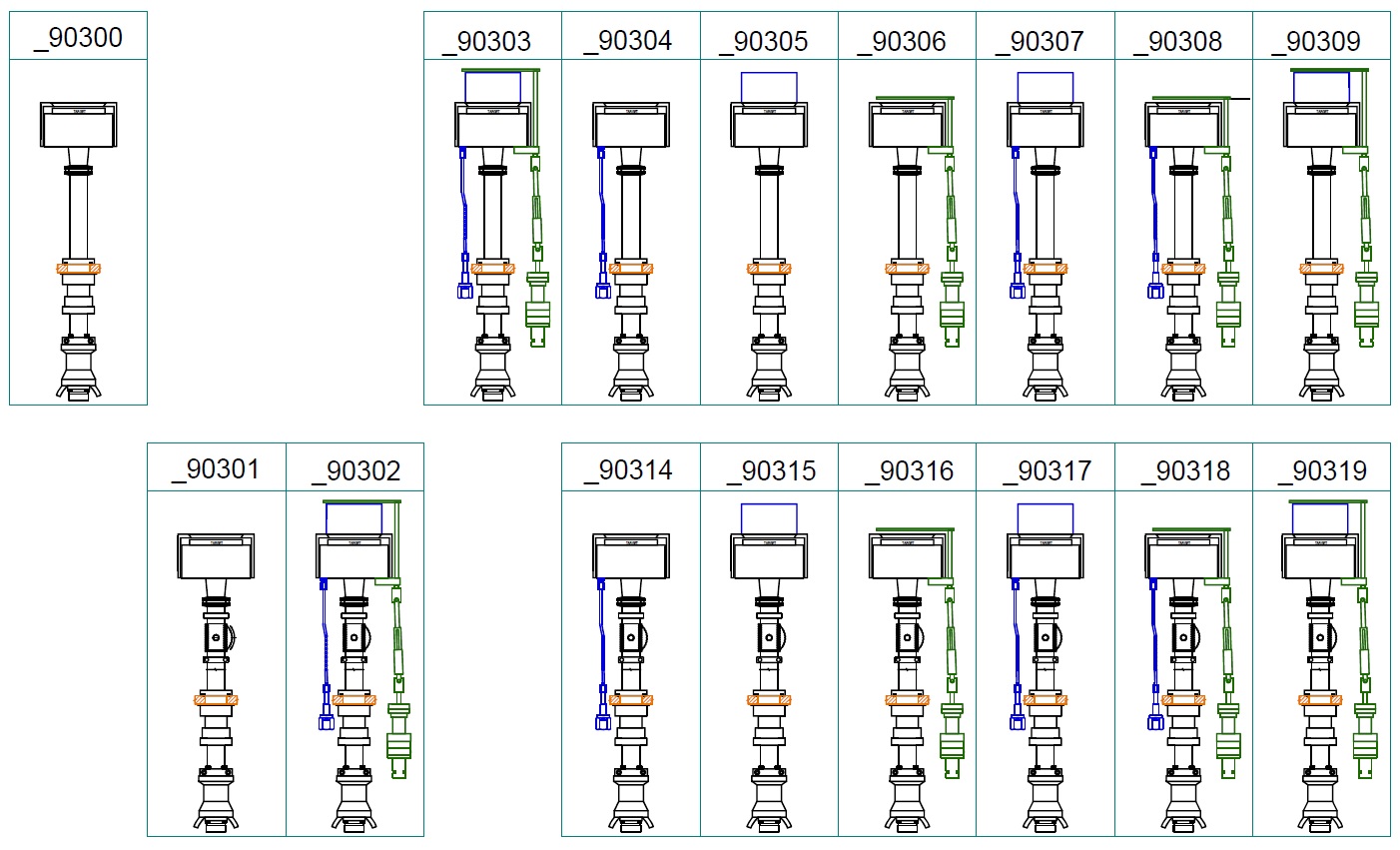

Possible Configurations

IONIX® circular HV magnetron assemblies

All IONIX® HV sputtering sources can be mounted to outer diameter 1'' tubes (or outer diameter 1.25'' tubes from Ø10'' on). A quick coupling feedtrough allows mounting trough base plate holes and easy adjustment of target-to-substrate distance. In addition, magnetron assemblies are avialable with gas distribution and pneumatic shutter.

Technical data

| IONIX® Ø2'' HV | IONIX® Ø3'' HV | IONIX® Ø4'' HV | IONIX® Ø6'' HV |

|

|

|

|

| Read more-> | Read more-> | Read more-> | Read more-> |

Possible Configurations

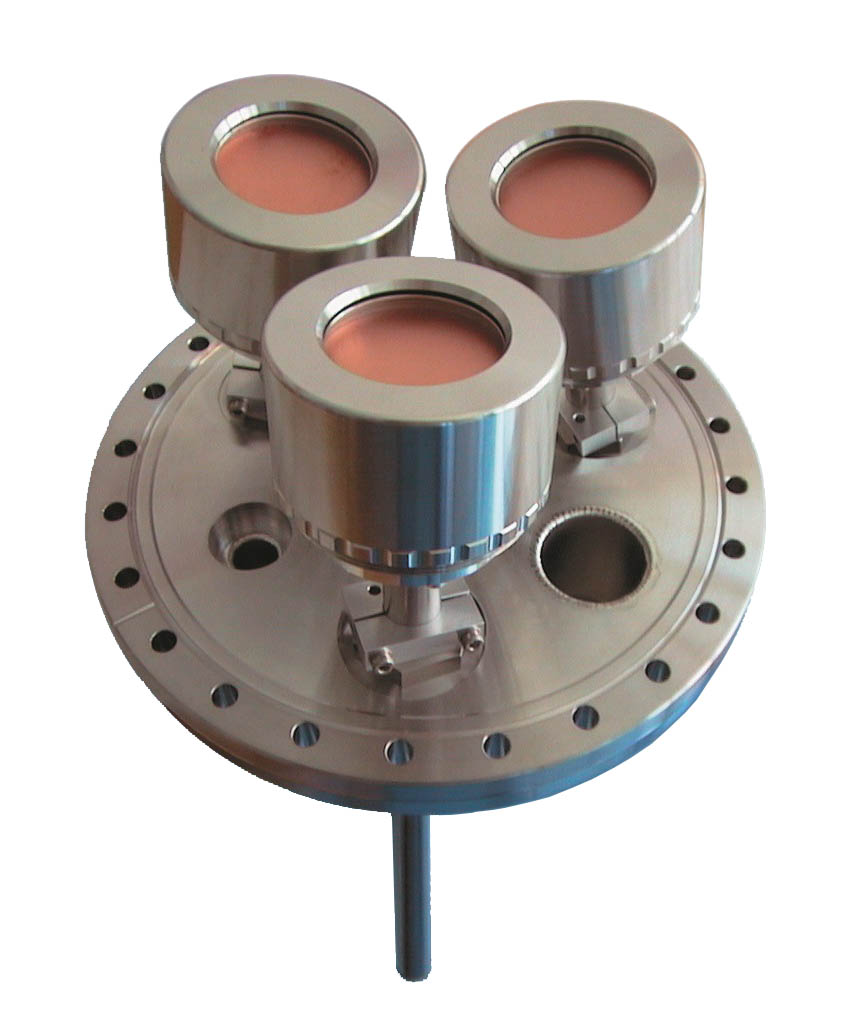

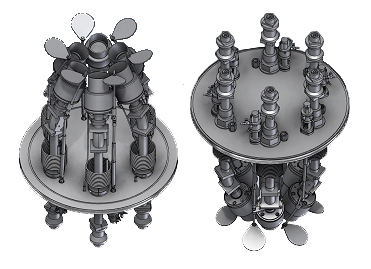

IONIX® circular HV Cluster solutions

|

|

|

Due to the IONIX® modular design a huge variety of HV cluster flanges can be made incorporating from 2 - 8 sputtering sources on a single vacuum flange. Individual sputtering sources can be equipped with pneumatic shutters, chimneys, z-shifts and gas distributions. Next to fixed angle solutions, cluster assemblies are avialable with manual or in-situ tilt allow confocal deposition.

In the latter case the focal point of the sputtering sources can be adjusted to adapt to different target-to-substrate distances and target materials. For such confocal arrangements typically two times the target diameter can be coated with +/- 5 % variation in film thickness uniformity and substrate rotation ( for example Ø4'' substrates can be coated with +/- 5 % by Ø2'' sputtering sources with substrate rotation).